Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DAYUE965

Transportation: Ocean,Land,Air,Express

Port: Yantian

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,Express Delivery,DAF,EXW,DES,DEQ,DDP

Iron,Cast iron.Copper,Stainless steel,Aluminum,WS,HSS,HWS Other non-ferrous metal (According to customer needs)

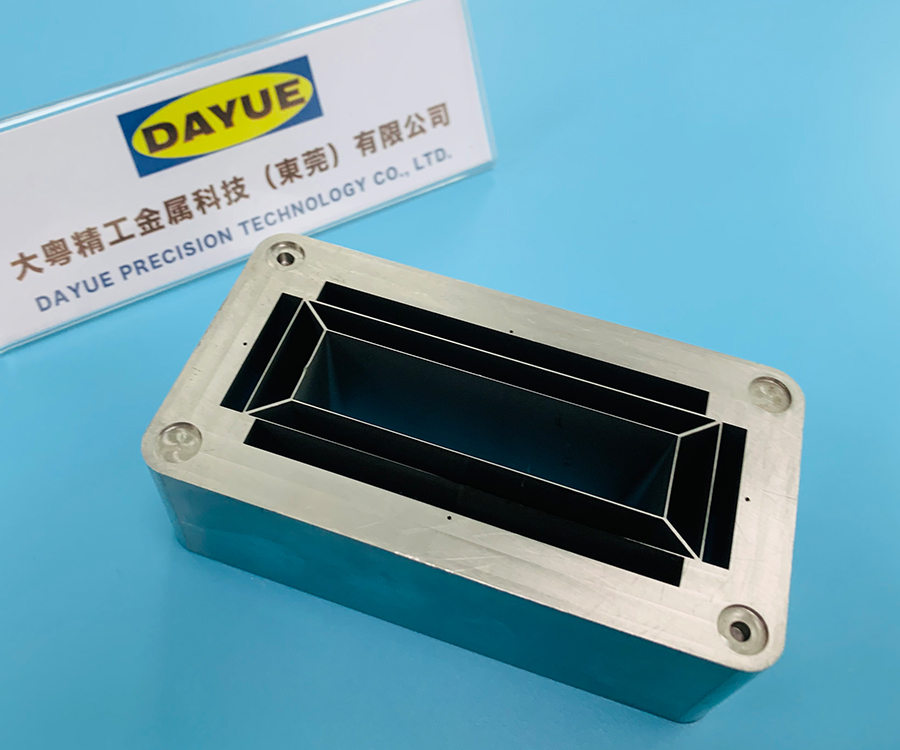

The use of slow-feeding wire has proven to be highly effective for machining thin-walled cavities in precision mold cavities. This technique involves using a thin wire electrode to cut through the material at a slow and controlled speed, which helps to minimize the risk of deformation or damage to the delicate walls of the cavity. The slow-feed wire method allows for precise and accurate machining, ensuring that the final product meets the required specifications. Additionally, this technique reduces the need for secondary operations and post-processing, resulting in time and cost savings. Overall, the use of slow-feeding wire has revolutionized the machining process for thin-walled cavities in precision Mold Cavities, offering improved efficiency and superior quality.

Product Categories : CNC Machined Parts > Wire EDM Components

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.