Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

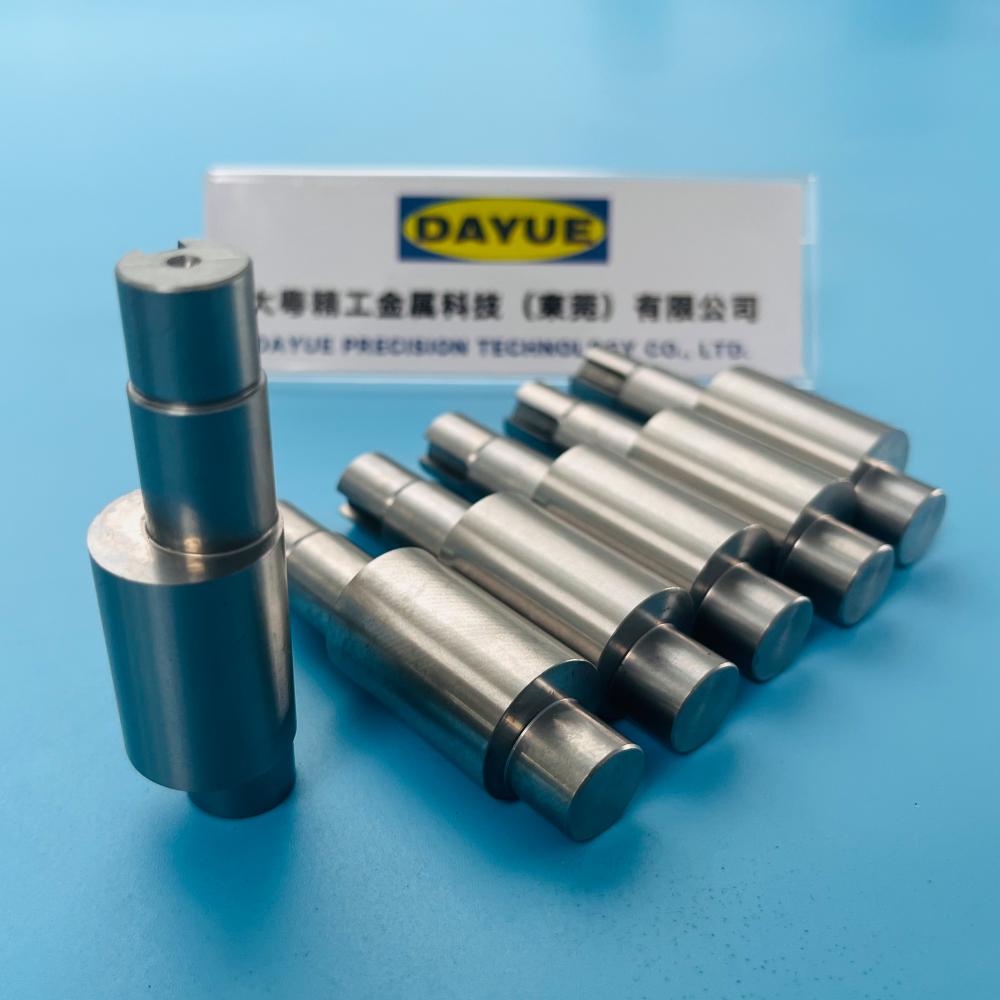

Hard Turning refers to the turning of hardened steel as a final machining or finishing process to avoid the commonly used grinding techniques. Turning is the most basic, extensive and important process in machinery manufacturing, which directly affects production efficiency, cost, energy consumption and environmental protection.

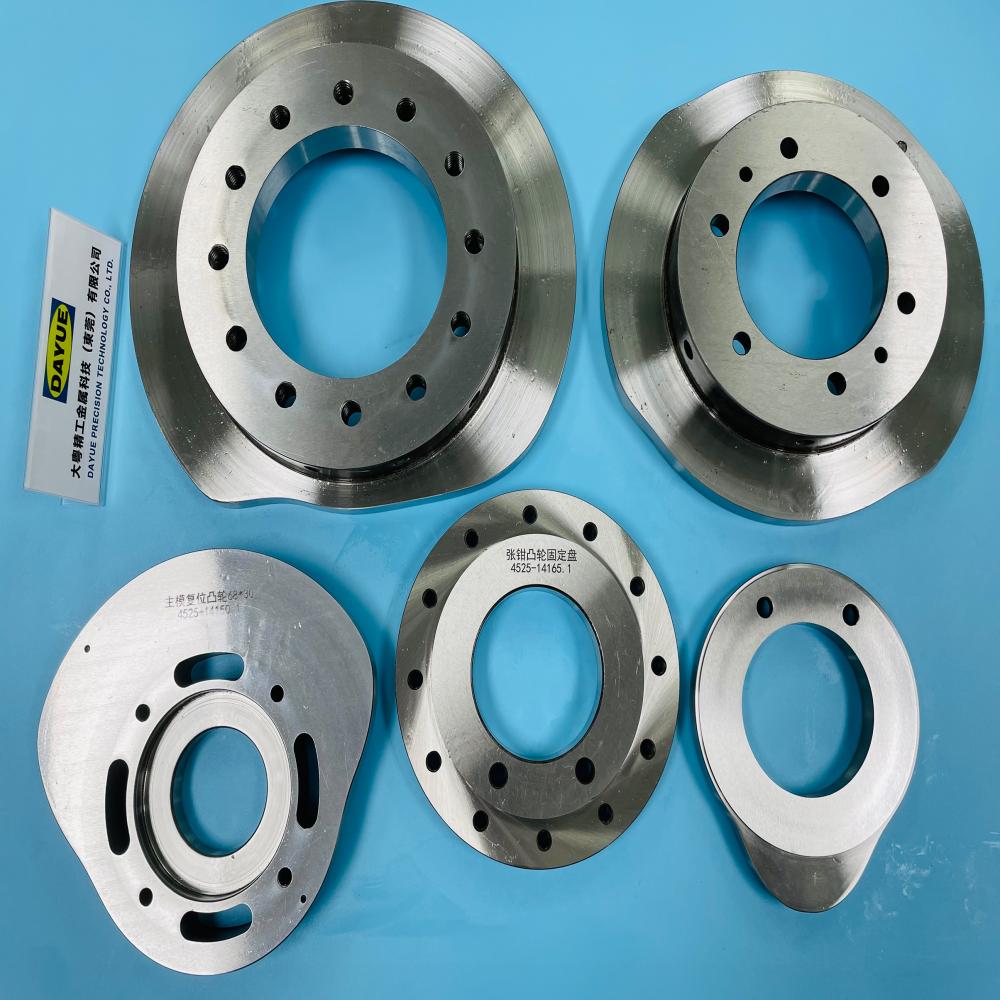

Our products also include CNC Turning, which refers to the process method of digitally controlled lathe processing. On the basis of traditional lathes, CNC systems and drive systems are added to form CNC lathes; there are also CNC Milling, which is a processing technology that uses Rotate the tool to remove the excess part of the material block until the desired customized shape is formed; there is also Electrical Discharge Machining, which refers to the electrical erosion of the workpiece through the pulse discharge between the tool electrode and the workpiece electrode in a certain medium. There is also Hard Turning which refers to the turning of hardened steel as a process method for final machining or finishing to avoid the commonly used grinding technology. If you want to know more, welcome to consult us, we will serve you wholeheartedly!

Previous: Knowledge About Die Springs

Next: What Is A Spur Gear

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.