Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

1. Rolling (close winding): The main inspection items are the section size, outer diameter and appearance of the spring steel wire. The section size and outer diameter should conform to the corresponding process parameters. There should be no scratches on the surface of the appearance, lodging of the spring coils is not allowed, and there should be no visible gap between the two coils of the spring;

2. Stress relief annealing: This process is to eliminate the internal stress generated by the spring during the rolling process, ensure the stability of the outer diameter and the number of turns when the spring is cut, and reduce the degree of quenching heating deformation. Taking the RJC-520CM continuous tempering furnace as an example for the TM50 series spring, the inspector should check whether the stress relief annealing temperature is set at 360℃, and whether the frequency of the crawler variable frequency motor is set at 5Hz, and make a record;

3. Cut-off spring: focus on checking the total number of turns and fracture quality. The deviation of the total number of turns is not allowed to exceed ±1/4 turn. Hooks and knife wounds are not allowed at the fracture.

4. Open thread pitch: focus on checking two points (1) The thread pitch t should be slightly smaller than the specified value of the process parameters to facilitate correction. (2) Both ends of the spring should be tight together, and there should be no visible gap.

5. Correction: focus on checking whether the pitch t and the height H before grinding meet the specified values of the process parameters. Taking the M50 series spring as an example, the inspection thread pitch t should be 13.2±0.5RaM, and the height before grinding should be H pre±0.5MM.

6. Grinding spring: In the spring grinding process, it is necessary to ensure that the thickness of the end, the grinding surface angle, and the roughness of the grinding surface meet the specified values of the process parameters. The key inspection (1) The thickness of the end should be b/4, and the minimum value should be b/8 ( b is the average thickness of the material). Take the TM40 series spring as an example, the thickness of the end should be 0.9~1.2MM. (2) The ground angle should be ≥270. (or 3/4 turn), the thickness of the grinding surface decreases evenly with the grinding surface angle.

7. Heat treatment: The purpose of spring heat treatment is to give full play to the potential of the material to achieve or approach better mechanical properties, so as to ensure long-term reliable operation of the spring in use. Die springs generally use annealed steel wire, which needs to be quenched and tempered.

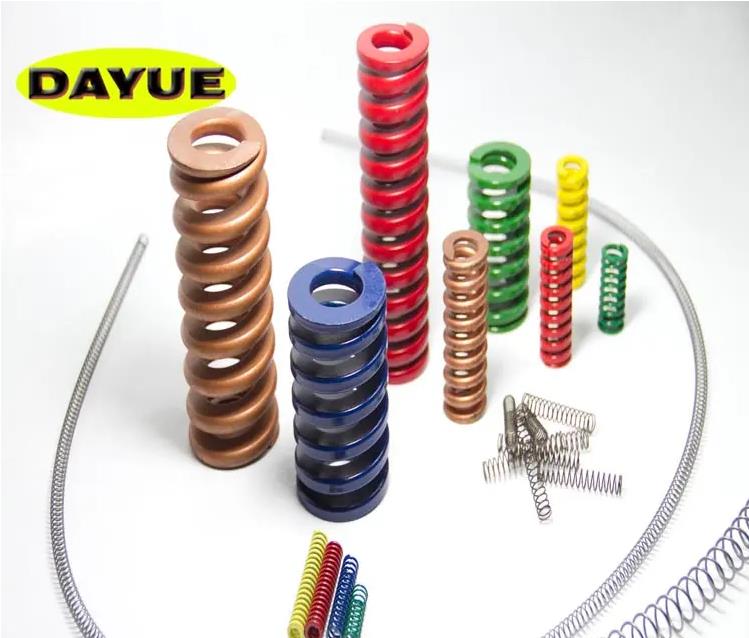

Looking for ideal ISO Medium Load Die Springs Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the ISO Standard Blue Springs are quality guaranteed. We are China Origin Factory of TJM ISO Standard Die Springs. If you have any question, please feel free to contact us.

Previous: CNC Machining And Working Principle

Next: What Is Hard Turning

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.