Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

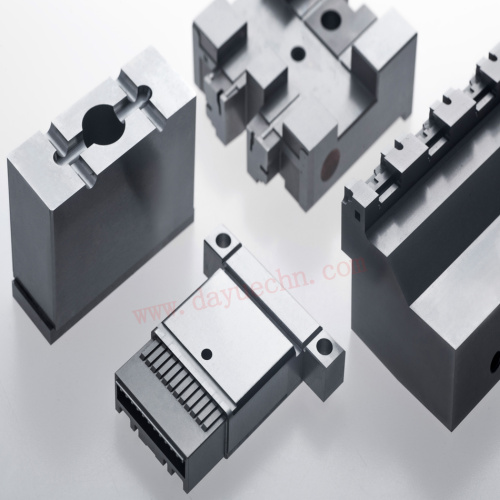

CNC Machined Parts(EDM) is a non-traditional machining process used to remove material from conductive materials by using electrical discharges or sparks.The process works by creating an electrical arc or spark between a tool electrode and the workpiece. The spark generates heat, which melts or vaporizes the material, and a small amount of material is removed from the workpiece. The tool electrode is usually made of a conductive material such as copper or graphite, and the workpiece is submerged in a dielectric fluid such as oil or deionized water, which helps to cool the machining area and conduct the electrical current.

The EDM process involves creating an electrical arc or spark between a tool (electrode) and the workpiece, which erodes the material from the workpiece to create the desired shape. The tool is usually made of a conductive material such as copper or graphite, and the workpiece is submerged in a dielectric fluid such as oil or deionized water to help conduct the electrical current and cool the machining area.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.