Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

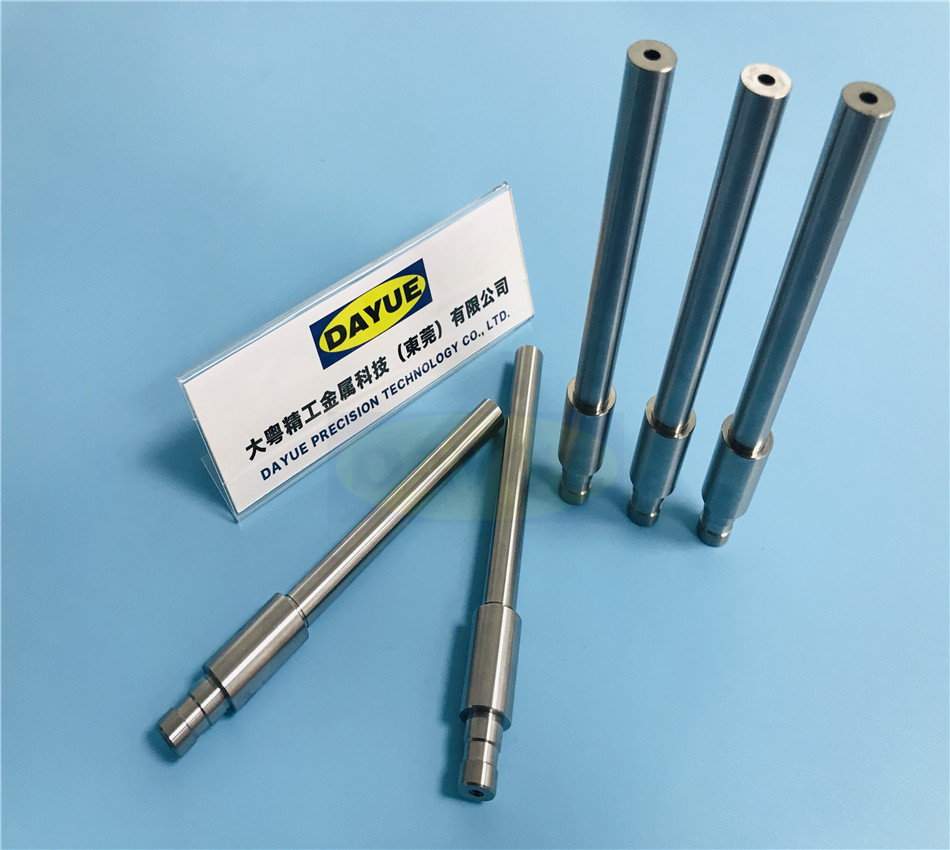

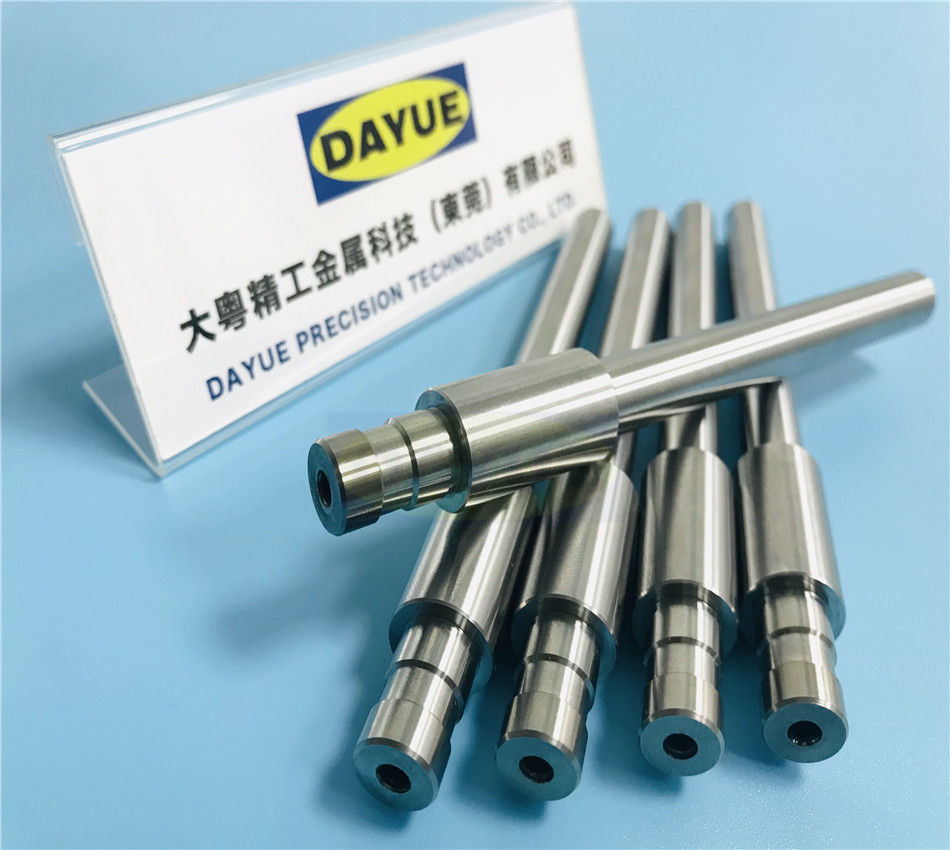

Model No.: DAYUE069

Brand: DAYUE

Application: Machinery Accessory

Standard: JIS Code

Surface Treatment: Polishing

Production Type: Batch Production

Machining Method: CNC Turning

Material: Iron

Packaging: Vacuum Packing

Productivity: 100 pieces a day

Transportation: Ocean,Land,Air

Place of Origin: Dongguan

Certificate: ISO9001

Port: Yantian

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

-Product information

Precision Grinding shaft core and shaft pin machining

1, processing technology to develop the basic principles

The position close to the tooling point is produced and processed first, and the position far from the tooling point is produced and processed later; the rough machining of the inner and outer surfaces is arranged first, followed by the finishing of the inner and outer surfaces; the program flow is made concise and clear, reducing the probability of errors and improving the efficiency of programming.

2、Division of the process

One installation, production and processing as a process: applicable to the production and processing of parts with less content; the same tool production and processing content to divide the process; production and processing location to divide the process applicable to the production and processing of many parts.

3、Clamping method

The general fixture of CNC lathe is chuck, generally three-jaw chuck. When the three-jaw chuck is chosen for the production and processing of shaft parts, the axis of the parts should coincide with the centre line of the chuck, and usually no correction is required, and the clamping speed is relatively fast.

For parts with high accuracy requirements, the following production and processing methods are more commonly used.

Two top clamping: for longer or must be completed by several clamping to production processing. Such as long shafts, screw rods, etc.. The clamping is convenient, does not need to find the right, the clamping accuracy is high. However, the centre hole must be drilled in the end face of the workpiece before clamping.

One-top clamping: Although the workpiece is clamped with two tops with high accuracy, the rigidity is relatively poor and affects the cutting amount. Turning usually shaft parts, especially heavier workpieces, can not be clamped with two tops, but with one end clamped and the other end topped with a back top clamping method.

Translated with www.DeepL.com/Translator (free version)

precision parts manufacturers and suppliers in China

-Standards compliant

Manufacturing diameter from φ0.01mm-φ650mm, tolerance can be controlled to ± 0.001

The longest manufacturing length is 1500mm

Manufactured in Inch size also for specials and custom parts.

According to the part design, the maximum concentricity can reach 0.002.

Surface finish:Ra0.2-Ra0.8

Slow walking wire reaches tolerance ± 0.001

EDM tolerance can reach ± 0.002

-material(Choose according to customer requirements)

Iron,Cast iron.Copper,Stainless steel,Tungsten carbide, steel,Aluminum,WS,HSS,HWS Other non-ferrous metal (According to customer needs)

Product Categories : Custom Mechanical Components > Shaft Components

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.