Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

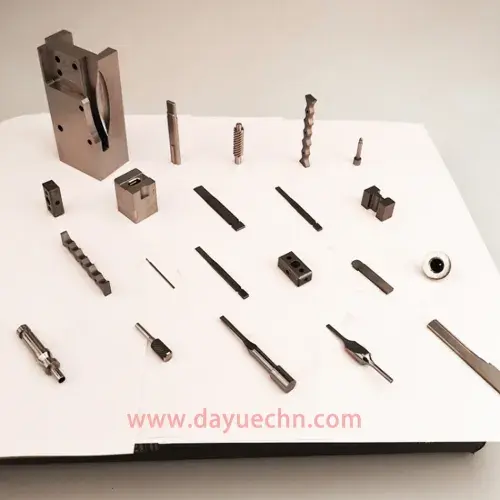

Core Pins are components of injection molding, which is a process used to manufacture plastic parts. During the process, plastic is injected into a mold and solidified to create a desired shape. The shape of the mold is created by two halves that are held together by a number of core pins. These pins act as support structures and create the pathways within the mold through which the plastic is injected.

Core pins are subject to significant amounts of stress and wear during the injection molding process, which can lead to damage or failure over time. For this reason, they are often coated with specialized materials, such as titanium nitride, to increase their hardness, durability, and resistance to wear.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.