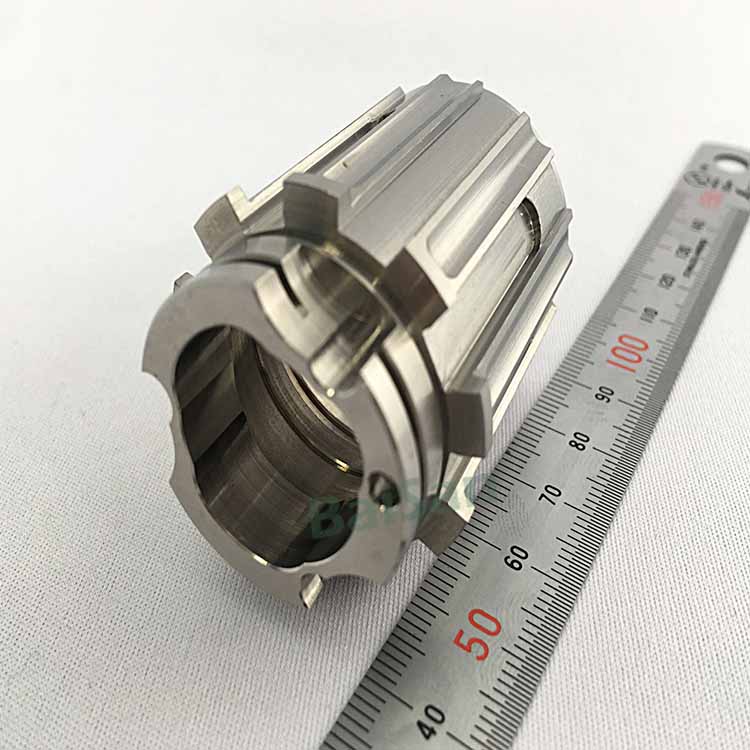

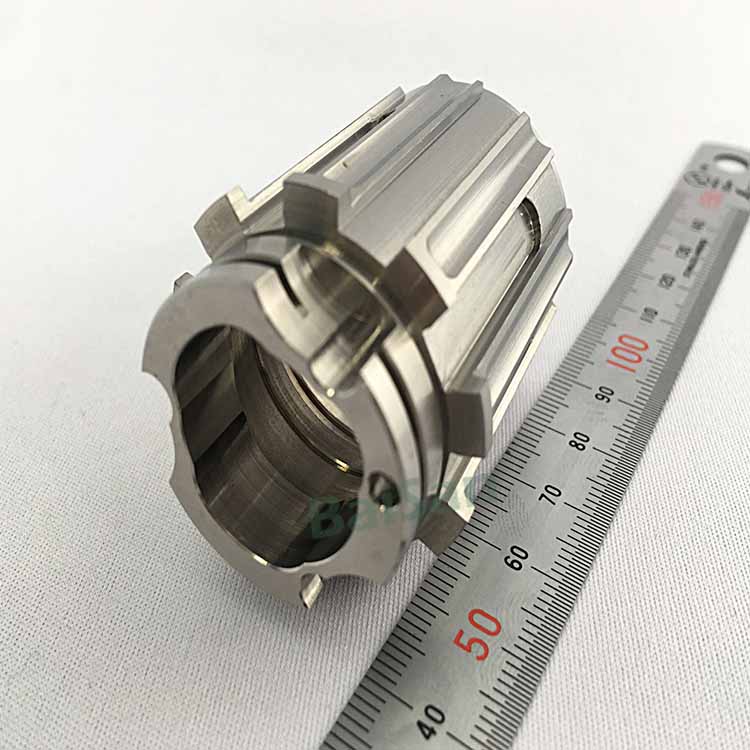

Processing Technology Of CNC Grinding Of Aerospace Valve Core

2023-11-17

Grinding machining of aerospace valve spool cores using CNC (Computer Numerical Control) technology is a precise and sophisticated process that plays a crucial role in the manufacturing of high-performance Aerospace Components. Here is an overview of the key aspects involved in aerospace valve spool core CNC grinding machining:  1. Material Selection: Aerospace valve spool cores are often made from high-strength and heat-resistant materials such as titanium alloys or stainless steel. The choice of material depends on the specific application and performance requirements. 2. Precision CNC Grinding: CNC grinding machines are employed for their exceptional precision and repeatability. These machines use computer-controlled movements to remove material from the valve spool core with high accuracy. The CNC programming defines the tool paths, grinding depths, and other parameters, ensuring consistency and conformity to tight tolerances. 3. Tooling and Abrasives: Specialized grinding wheels and abrasives are used to shape and finish the aerospace valve spool core. These tools are selected based on the material being machined and the desired surface finish. CNC programming specifies the type of grinding wheel, its speed, and the depth of cut to achieve the required dimensional and surface quality. 4. Coolant and Lubrication: Coolant is often used during the CNC grinding process to dissipate heat generated by friction and prevent thermal damage to the aerospace valve spool core. Lubrication may also be applied to reduce friction and wear on the grinding tools, extending their lifespan. 5. Quality Control and Inspection: Throughout the CNC grinding process, quality control measures are implemented to ensure the aerospace valve spool core meets the required specifications. 6. Surface Finish and Coating: Achieving the appropriate surface finish is crucial for aerospace applications. CNC grinding allows for the production of smooth and precisely finished surfaces. In some cases, additional coatings or treatments may be applied to enhance wear resistance, corrosion resistance, or other specific performance characteristics. 7. Documentation and Traceability: Comprehensive documentation is maintained throughout the CNC grinding process, providing traceability and ensuring that each aerospace valve spool core can be linked back to its specific manufacturing parameters. 8. Environmental Considerations: Aerospace machining facilities adhere to stringent environmental standards. Measures are taken to manage and control the disposal of machining by-products, coolant, and other waste materials in an eco-friendly manner. Conclusion: Aerospace valve spool core CNC grinding machining represents a highly advanced and precise manufacturing process that demands meticulous attention to detail. This process, characterized by precision CNC programming, specialized tooling, and stringent quality control measures, contributes to the production of aerospace components that meet the industry's demanding standards for performance and reliability.

1. Material Selection: Aerospace valve spool cores are often made from high-strength and heat-resistant materials such as titanium alloys or stainless steel. The choice of material depends on the specific application and performance requirements. 2. Precision CNC Grinding: CNC grinding machines are employed for their exceptional precision and repeatability. These machines use computer-controlled movements to remove material from the valve spool core with high accuracy. The CNC programming defines the tool paths, grinding depths, and other parameters, ensuring consistency and conformity to tight tolerances. 3. Tooling and Abrasives: Specialized grinding wheels and abrasives are used to shape and finish the aerospace valve spool core. These tools are selected based on the material being machined and the desired surface finish. CNC programming specifies the type of grinding wheel, its speed, and the depth of cut to achieve the required dimensional and surface quality. 4. Coolant and Lubrication: Coolant is often used during the CNC grinding process to dissipate heat generated by friction and prevent thermal damage to the aerospace valve spool core. Lubrication may also be applied to reduce friction and wear on the grinding tools, extending their lifespan. 5. Quality Control and Inspection: Throughout the CNC grinding process, quality control measures are implemented to ensure the aerospace valve spool core meets the required specifications. 6. Surface Finish and Coating: Achieving the appropriate surface finish is crucial for aerospace applications. CNC grinding allows for the production of smooth and precisely finished surfaces. In some cases, additional coatings or treatments may be applied to enhance wear resistance, corrosion resistance, or other specific performance characteristics. 7. Documentation and Traceability: Comprehensive documentation is maintained throughout the CNC grinding process, providing traceability and ensuring that each aerospace valve spool core can be linked back to its specific manufacturing parameters. 8. Environmental Considerations: Aerospace machining facilities adhere to stringent environmental standards. Measures are taken to manage and control the disposal of machining by-products, coolant, and other waste materials in an eco-friendly manner. Conclusion: Aerospace valve spool core CNC grinding machining represents a highly advanced and precise manufacturing process that demands meticulous attention to detail. This process, characterized by precision CNC programming, specialized tooling, and stringent quality control measures, contributes to the production of aerospace components that meet the industry's demanding standards for performance and reliability.