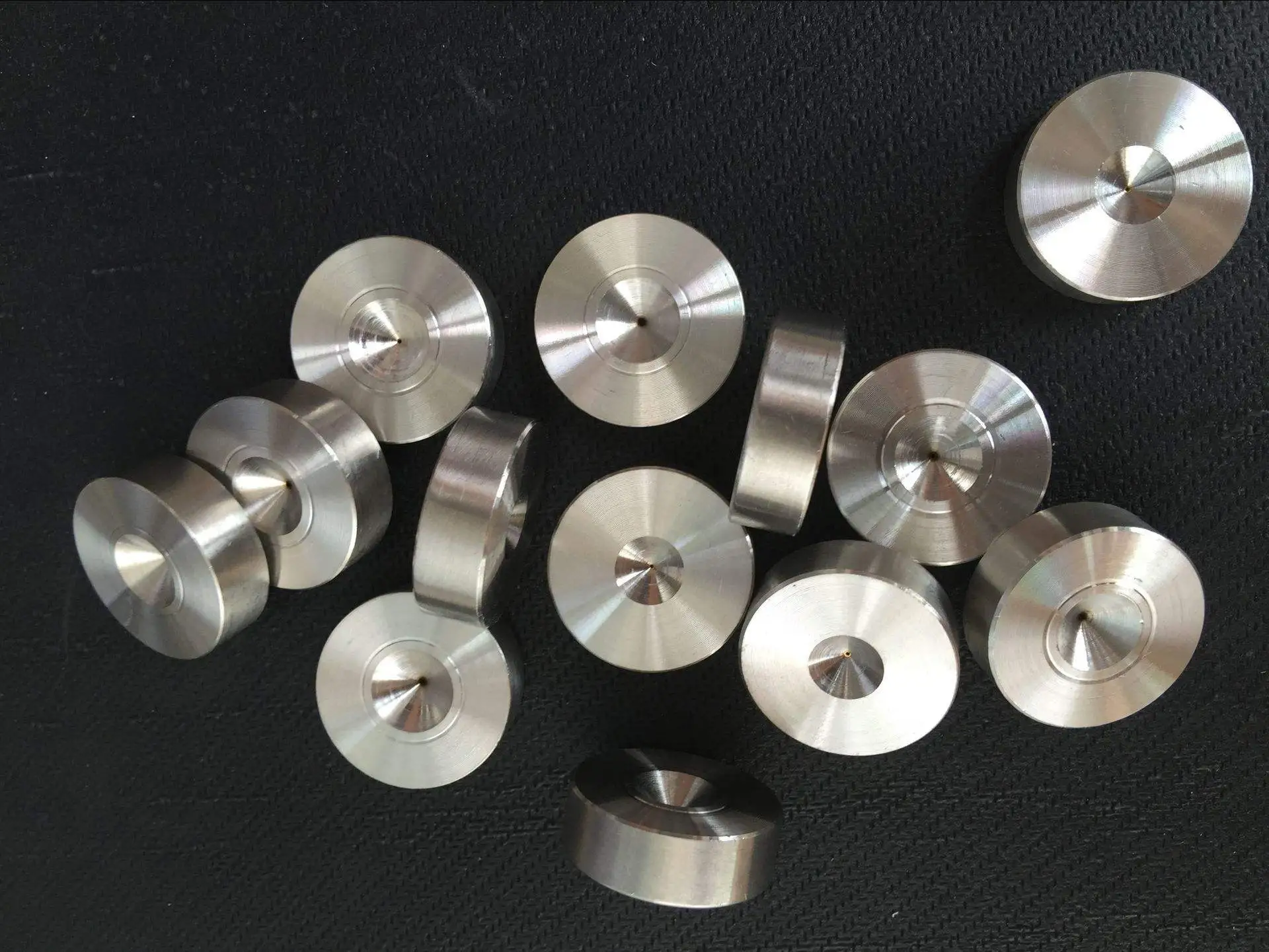

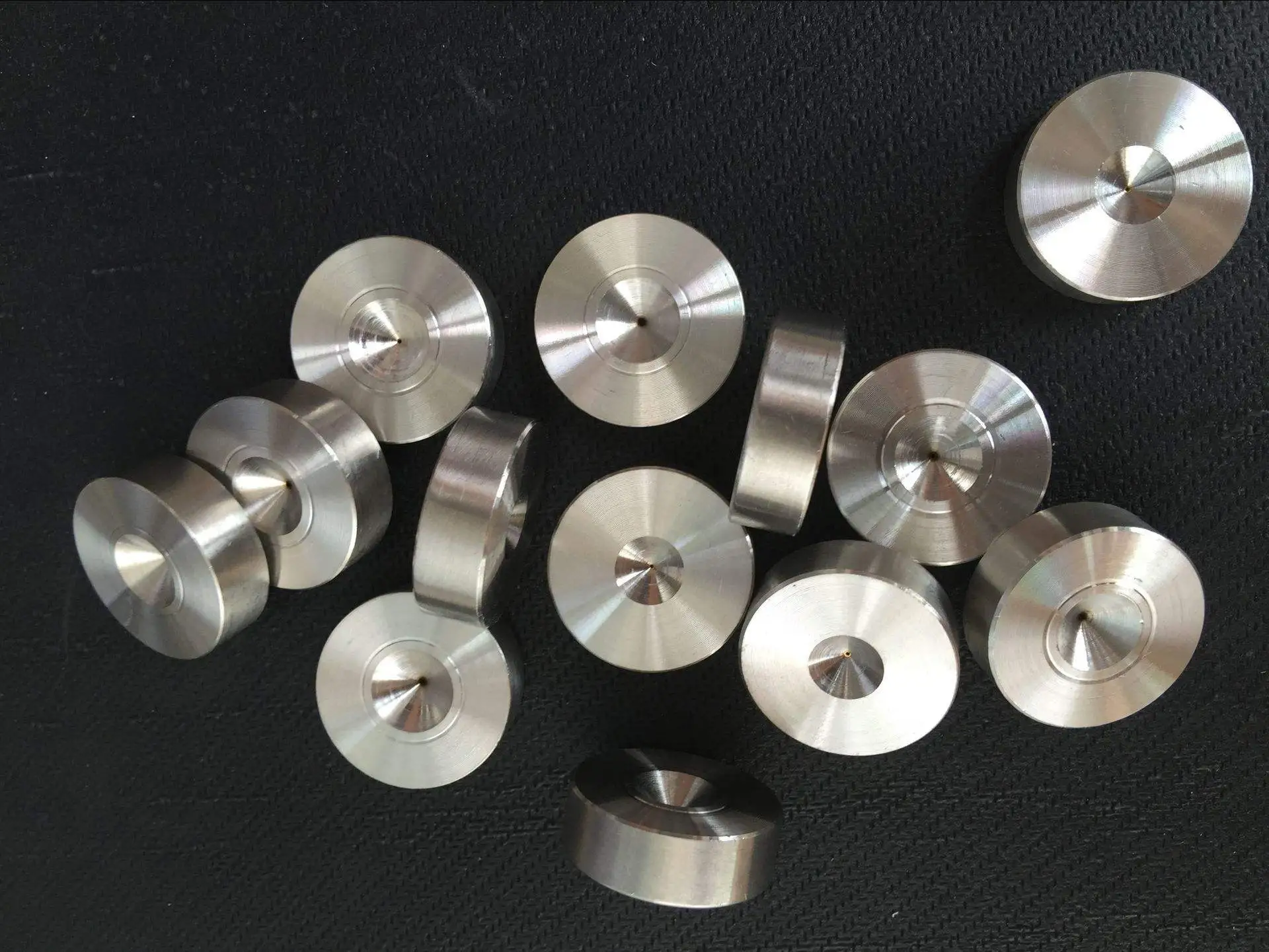

Precision CNC Machining actually refers to numerical control machining. After programming the drawings to be processed into the program, the computer is connected to the cnc processing machine tool, and the cnc processing machine tool is commanded to operate through programming to complete the precision parts processing. Precision cnc processing is mainly suitable for small-batch and large-batch processing of various types of spare parts. CNC Machined Parts has very high precision, so it serves the processing of precision parts in different industries. The following editor will introduce to you the process flow of precision cnc machining.

First of all, before machining CNC parts, you must clearly see the process flow, clearly know the parts, shapes, and dimensions of the drawings to be processed, and know the processing content of the next process. Before clamping raw materials for processing, measure whether the size of the blank meets the requirements of the drawing, and carefully check whether its placement is consistent with the programmed instructions. After the rough machining of the processing technology is completed, self-inspection should be carried out in time, so that the data with errors can be adjusted in time. The content of the self-inspection is mainly the position and size of the processing part. How to self-check the processing technology? 1. Whether there is looseness during the processing of mechanical parts; 2. Whether the processing technology of parts is correct or not; 3. Whether the size from the part processed by CNC parts to the reference edge (reference point) meets the requirements of the drawing; 4. The position and size of the cnc processing parts. After checking the position size, measure the rough shape ruler (except the arc). Want to know more about our products CNC Turning, CNC Milling, Electrical Discharge Machining, please contact us.

The parts are finished after the rough machining is confirmed. Carry out self-inspection on the shape and size of the drawing parts before finishing: check the basic length and width dimensions of the processing parts on the vertical surface; measure the base point size marked on the drawing for the processing parts on the inclined plane. After completing the self-inspection of the parts and confirming that they meet the drawings and process requirements, the workpiece can be removed and sent to the inspector for special inspection. When encountering precision cnc parts processing and small batch processing, batch processing is required after the first part is confirmed to be qualified. The above content is an introduction to the process of precision cnc machining. CNC machining center machine tools have high precision and have unique advantages for high precision, complex, and small batch parts processing; Precision Grinding machines are one of the precision machining equipment, mainly for finishing , mainly for the processing of quenched parts; CNC lathes are also automatic processing equipment, generally processing shafts, rods, and round parts, and have advantages for special precision requirements or small batch parts processing.