Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DAYUE0046

Transportation: Ocean,Land,Air,Express

Port: Tantian

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,EXW,FCA,DDP,DDU,Express Delivery

-Product Information

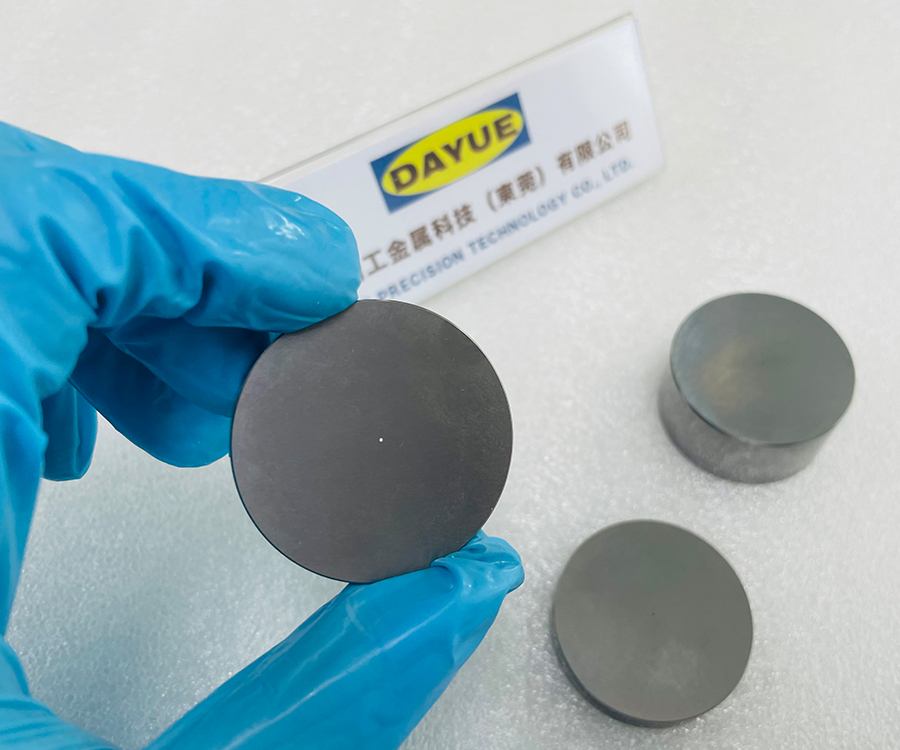

-DAYUE Precision Parts Manufacturing Factory, We have several factories in China. Specialized in processing all kinds of Precision Mold Parts, mechanical parts, carbide molds, tungsten carbide non-standard parts, tungsten steel machining, automation equipment components, FA automation parts Valve Components, medical device parts and other various precision parts manufacturing.

-Our advantage is heat-treated parts, we are good at secondary finishing by internal and external grinding, slow walking wire, mirror discharge, honing, PG optical grinder, gun drilling deep hole drilling and so on.

-Our diameters can generally reach ±0.001, white steel finish up to 0.4, tungsten steel finish up to 0.1.

Microporous parts are highly specialized components that are designed to have small pores or openings on their surface. These parts are commonly used in various industries such as automotive, electronics, medical, and aerospace.

Product Categories : CNC Machined Parts > Electrical Discharge Machining

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.