Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DAYUE001

Brand: DAYUE

Application: Machinery Accessory

Standard: JIS Code

Surface Treatment: Polishing

Production Type: Batch Production

Machining Method: CNC Turning

Material: Iron

Packaging: Vacuum Packing

Productivity: 100 pieces a day

Transportation: Ocean,Land,Air

Place of Origin: Dongguan

Certificate: ISO9001

Port: Yantian

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

-Product information

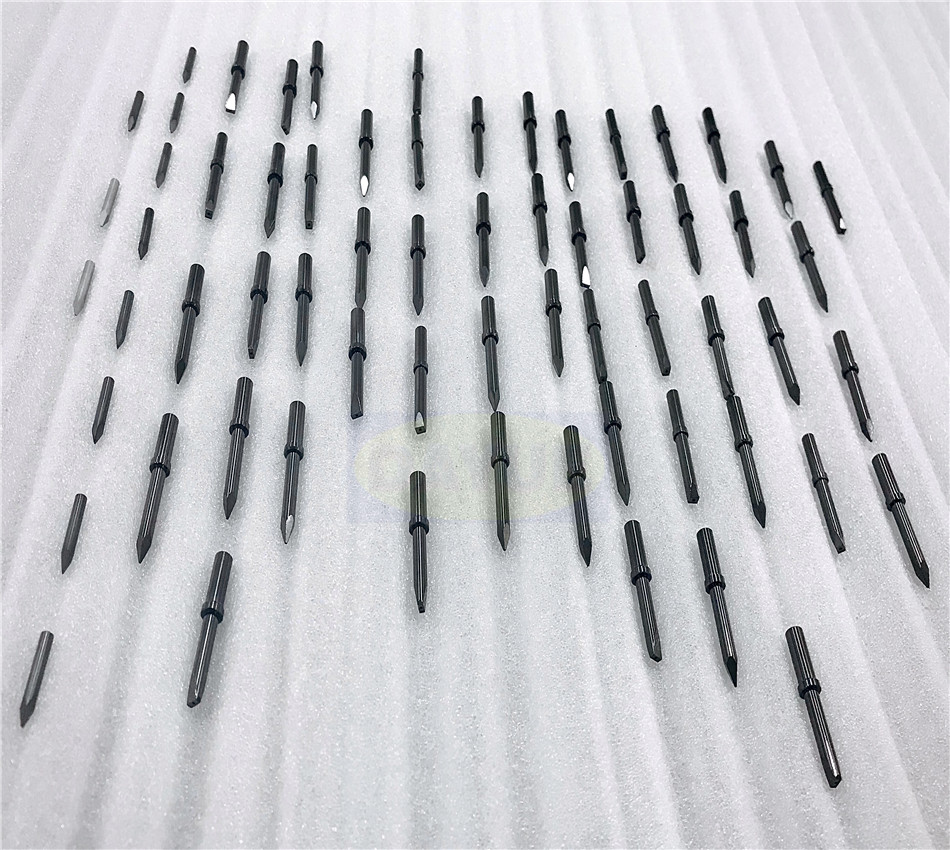

Micro-holes small holes Processing EDM machining Mold Parts

CNC Turning & CNC Milling service manufacturers suppliers in China

When the number of parts machined by EDM is below 3000, it is economically more reasonable than die stamping parts. EDM can be broadly divided into EDM forming, EDM wire-cutting, EDM grinding, EDM spreading, non-metallic EDM and EDM surface strengthening according to the characteristics and uses of the relative movement of the tool and the workpiece during the process.

(1) EDM processing This method is to process the required parts by replicating the shape and size of the workpiece electrode on the workpiece through the feed motion of the tool electrode relative to the workpiece. It includes EDM cavity machining and piercing machining. EDM cavity machining is mainly used for machining the cavities of various types of hot forging dies, die casting dies, extrusion dies, plastic dies and mylar films. EDM perforation is mainly used for the processing of shaped holes (round holes, square holes, polygonal holes, shaped holes), curved holes (curved holes, spiral holes), small holes and micro holes. In recent years, in order to solve the problems of small electrode cross-section, easy deformation, large hole depth to diameter ratio and difficult chip removal in small hole machining, high speed small hole machining has been developed in EDM piercing and good social and economic benefits have been achieved.

(2) EDM wire cutting processing The method is the use of moving fine metal wire as a tool electrode, according to the predetermined trajectory for pulse discharge cutting. According to the size of the speed of the metal wire electrode movement is divided into high-speed wire walking and low-speed wire cutting. China's common use of high-speed wire cutting, in recent years is the development of low-speed wire cutting, high-speed wire, wire electrode is φ0.02 ~ φ0.3mm diameter of high-strength molybdenum wire, reciprocating movement speed of 8 ~ 10m / s. Low-speed wire, more copper wire, wire electrode to less than 0.2m / s speed for single direction low-speed movement. When wire cutting, the electrode wire is constantly moving, its loss is very small, and thus the processing accuracy is high. The average machining accuracy can reach 0.0lmm, which is much higher than that of EDM. The surface roughness Ra value can be 1.6 or less.

Domestic and foreign CNC EDM machine tools have adopted different levels of microcomputer numerical control system, to achieve the EDM wire cutting CNC. At present, EDM wire cutting is widely used for processing various punching dies (for punching and falling material), sample plates and various shapes of complex type holes, type surfaces and narrow slits, etc.

-Standards compliant

Manufacturing diameter from φ0.01mm-φ650mm, tolerance can be controlled to ± 0.001

The longest manufacturing length is 1500mm

Manufactured in Inch size also for specials and custom parts.

According to the part design, the maximum concentricity can reach 0.002.

Surface finish:Ra0.2-Ra0.8

Slow walking wire reaches tolerance ± 0.001

EDM tolerance can reach ± 0.002

-material(Choose according to customer requirements)

Iron,Cast iron.Copper,Stainless steel,Tungsten carbide, steel,Aluminum,WS,HSS,HWS Other non-ferrous metal (According to customer needs)

Product Categories : Press Die Components > Processing According to Drawings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.