CNC Turning is a key manufacturing process utilized in various industries, including automotive, aerospace, electronics, and more. It involves the use of computer numerical control (CNC) machines to shape and machine solid materials, such as metal or plastic, into intricate and precise components. CNC turning is known for its efficiency, accuracy, and versatility, making it an essential technology in modern manufacturing. Let's explore the three key characteristics of CNC turning in detail.

1. Precision and Accuracy: One of the most prominent characteristics of CNC turning is its exceptional precision and accuracy. CNC turning machines are equipped with advanced computer-controlled systems that ensure precise movements and positioning of the cutting tools. The computer programs, or CNC codes, guide the machine in executing the desired operations with meticulous detail. This level of precision and accuracy is especially crucial in industries where even the smallest tolerance variations can lead to significant issues. CNC turning can consistently produce components with tight tolerances, ensuring that each piece meets the required specifications. The ability to achieve high precision and accuracy in CNC turning leads to improved product quality, reduced waste, and enhanced performance of the manufactured parts. 2. Automation and Efficiency: Another characteristic of CNC turning is its automation and efficiency. The CNC machines used in this process are designed to operate autonomously, guided by pre-programmed instructions. Once the program is loaded and the machine is set up, it can run continuously without constant human intervention. This automation feature allows for increased productivity and efficiency, as multiple machining operations can be performed without the need for manual adjustments or tool changes. Furthermore, CNC turning machines are capable of performing complex operations with minimal setup time. The ability to quickly switch between cutting tools, adjust feed rates, and execute intricate tool paths streamlines the manufacturing process. CNC turning eliminates the need for manual adjustments and reduces the risk of human error, resulting in higher productivity and faster turnaround times.

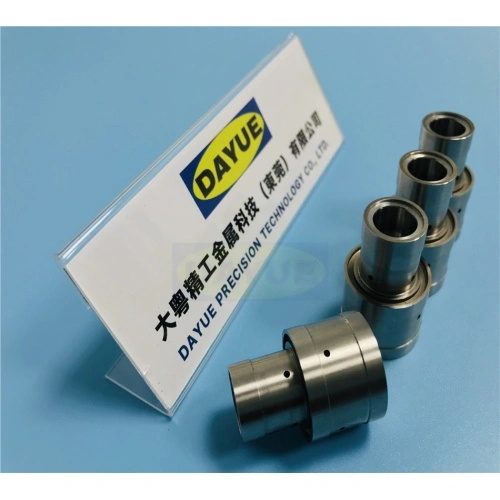

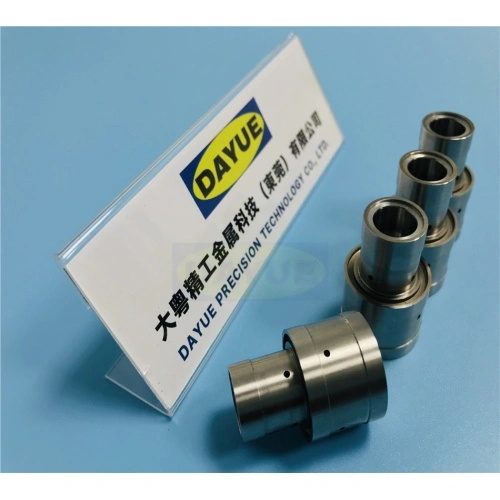

3. Versatility and Flexibility: CNC turning offers versatility and flexibility in terms of the range of materials that can be machined and the complexity of geometries that can be achieved. These machines can work with a wide variety of materials, including metals like steel, aluminum, brass, and titanium, as well as plastics and composites. The cutting tools used can be selected based on the specific material properties, ensuring optimal results and long tool life. Moreover, CNC turning can handle complex geometries with ease. The machines' multi-axis capabilities allow for intricate cuts, thread machining, grooving, and contouring with high precision. Additionally, CNC turning machines can be programmed to produce a wide range of components, from simple cylindrical shapes to intricate designs with various features. This versatility and flexibility in CNC turning make it suitable for a diverse range of applications across numerous industries. Our company also produces Aluminum Alloy Components and OEM/ODM Brass components, if you have any needs, please contact us.