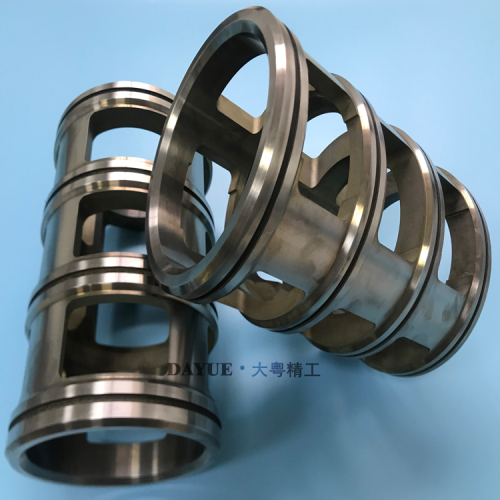

Machining Excellence in Hydraulic Valve Bushings for Oilfield Applications

2023-12-22

In the dynamic and demanding oilfield industry, the efficient and precise performance of hydraulic systems is critical. Hydraulic valve bushings play a pivotal role in ensuring the seamless operation of valves within these systems. This article explores the machining processes involved in crafting hydraulic valve bushings for oilfield applications, emphasizing the importance of precision and reliability in their production. I. Material Selection: The first step in machining hydraulic valve bushings is the careful selection of materials. Given the harsh conditions and corrosive environments encountered in oilfield applications, materials with high strength, corrosion resistance, and durability are essential. Common materials include various grades of stainless steel and alloys, chosen for their ability to withstand the challenging conditions prevalent in oil and gas operations. II. Precision Machining Techniques: Precision machining is paramount in the production of hydraulic valve bushings. Computer Numerical Control (CNC) machining is often employed to ensure accuracy and repeatability in the manufacturing process. CNC machines utilize computer programming to control the cutting tools, resulting in tight tolerances and consistent quality. This level of precision is crucial to guarantee the proper fit and functionality of the valve bushings within the hydraulic system. III. Turning and Milling Operations: Turning and milling are fundamental machining operations involved in crafting hydraulic valve bushings. Turning involves rotating the workpiece while a cutting tool removes material to create cylindrical shapes, while milling uses rotating cutting tools to remove material in a controlled manner. These operations shape the valve bushings to the exact specifications required for optimal performance in oilfield applications. IV. Surface Treatment and Coating: To enhance the durability and resistance of hydraulic valve bushings, surface treatment and coating processes are often applied. This may include techniques such as heat treatment, case hardening, or the application of specialized coatings like nitriding or chrome plating. These processes improve the wear resistance and corrosion protection of the bushings, ensuring a longer service life in the challenging conditions of oilfield operations. V. Quality Control and Inspection: Stringent quality control measures are implemented throughout the machining process. Advanced inspection tools, such as coordinate measuring machines (CMMs), are used to verify dimensional accuracy and ensure that each hydraulic valve bushing meets the specified tolerances. Quality control is crucial in guaranteeing the reliability and performance of the final product in oilfield applications. The machining of hydraulic valve bushings for oilfield applications demands a combination of advanced technology, precision machining techniques, and materials expertise. As these components play a critical role in the efficient operation of hydraulic systems in the challenging oil and gas industry, the emphasis on precision, durability, and quality control is paramount. The ongoing advancement of machining technologies and materials will continue to contribute to the reliability and performance of hydraulic valve bushings in oilfield applications.