Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DAYUE985

Transportation: Ocean,Land,Air,Express

Port: Yantian

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,Express Delivery,DAF,EXW,DDP,FCA

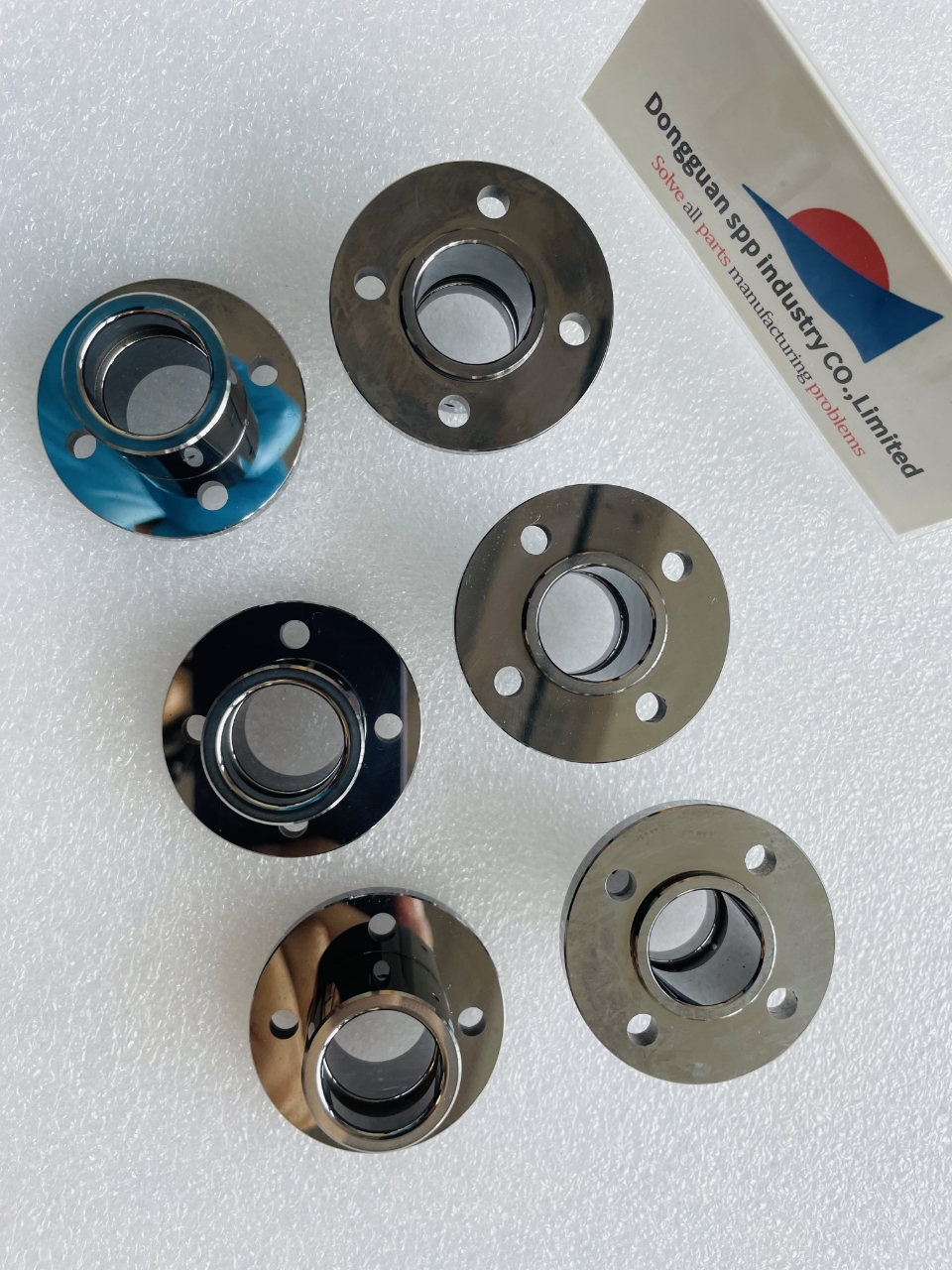

Iron,Cast iron.Copper,Stainless steel,Aluminum,WS,HSS,HWS Other non-ferrous metal (According to customer needs)

The production process of lithium battery carbide parts involves several steps to ensure the quality and performance of the final product. Firstly, raw materials such as lithium, graphite, and other additives are carefully selected and mixed in precise proportions. The mixture is then pressed into molds to form the desired shape of the carbide parts. Next, the molded parts are sintered at high temperatures in a controlled atmosphere to achieve the desired density and strength. After sintering, the parts undergo finishing processes such as grinding, polishing, and coating to improve their surface quality and performance. Finally, the finished carbide parts are inspected for quality control before being assembled into lithium batteries for use in various applications. The production process of lithium battery carbide parts requires precision, expertise, and attention to detail to ensure the reliability and efficiency of the final product.

Product Categories : CNC Machined Parts > Electrical Discharge Machining

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.