Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DAYUE103

Brand: DAYUE

Application: Machinery Accessory

Standard: JIS Code

Surface Treatment: Polishing

Production Type: Batch Production

Machining Method: CNC Turning

Material: Iron

Packaging: Vacuum Packing

Productivity: 100 pieces a day

Transportation: Ocean,Land,Air

Place of Origin: Dongguan

Certificate: ISO9001

Port: Yantian

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

-Product information

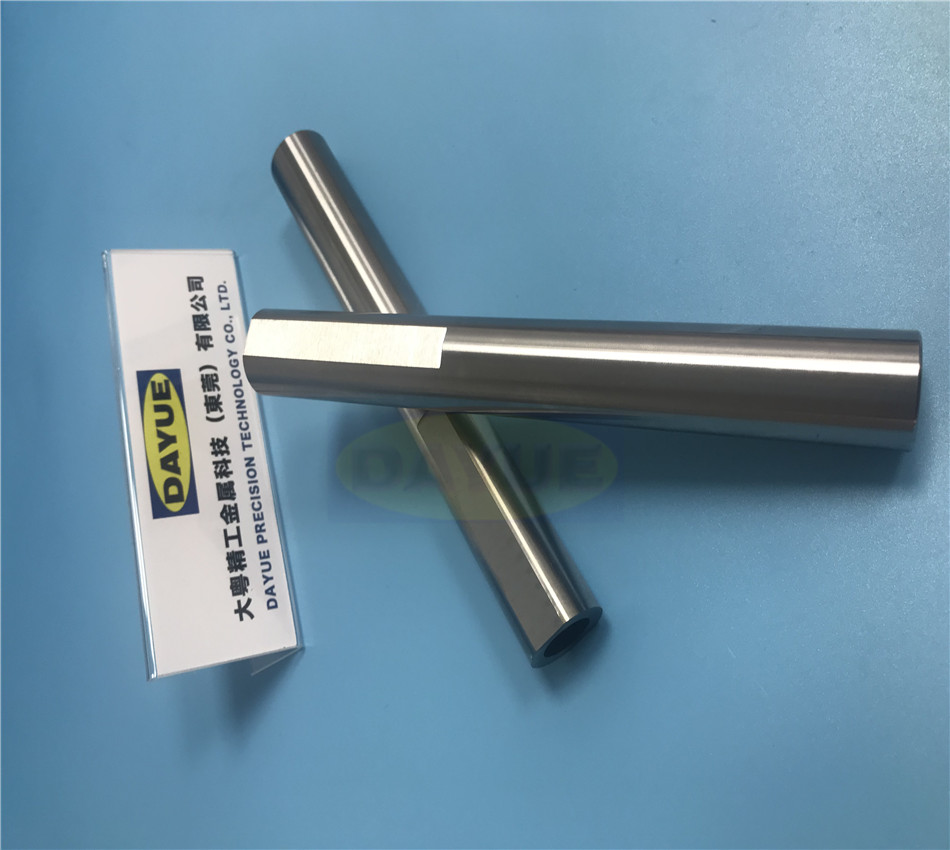

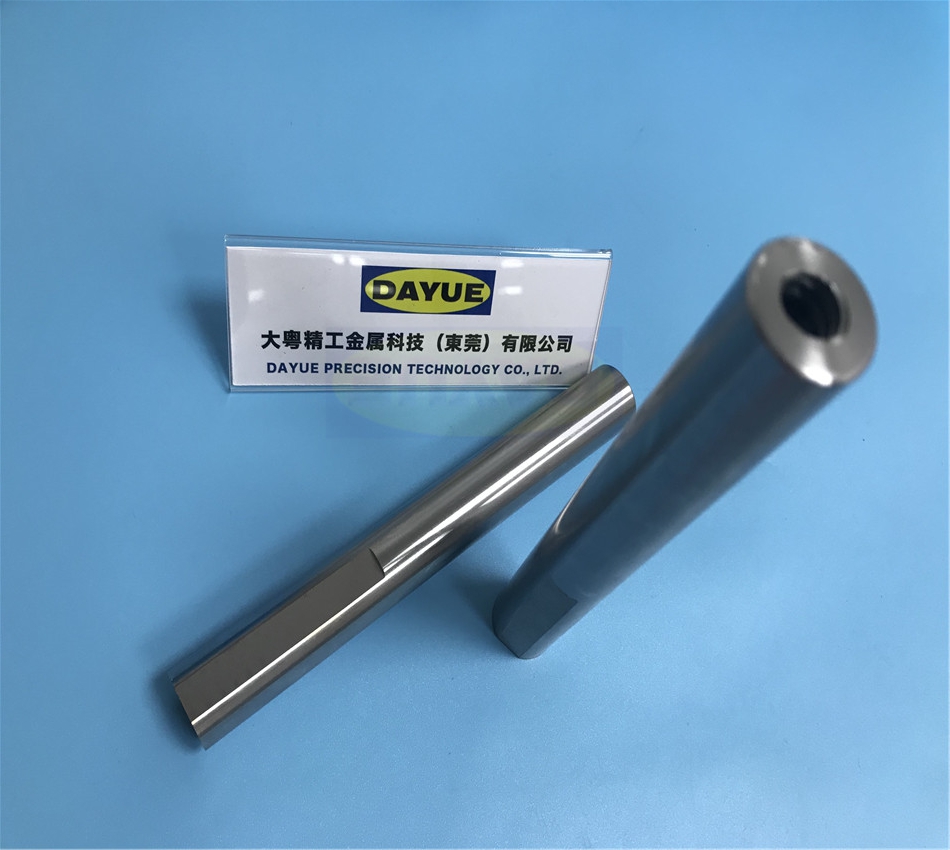

Surface grinder trimming processing mold push rod

Mold Parts and components manufacturers suppliers in China

1. Push rod eject precautions

(1)When the self-tapping screw column is high and cannot be pushed out with the push tube, attention should be paid to adding an extra push rod next to it so that the self-tapping screw column can be ejected smoothly.

(2)When there is a height difference in the plastic part, the push rod should be distributed in the part with higher viscous mould force, usually setting the push rod at a lower position has a better effect.

(3) from the processing considerations, the push rod is generally not lined up in the touch through the surface, from the finished edge A ≥ 0.5mm. push rod from the cooling water channel can not be too close, B ≥ 3mm safer.

(4) when the plastic part has a large and thin plane, even if the core of the injection mold processing is not wrapped tightly, but the adhesion force may also make the injection mold processing plastic deformation, so you must arrange the push rod, and push rod diameter can be as large as possible, the arrangement should be balanced.

(5) assembly with self-tapping screws to fix the rubber column usually have to add the push rod at the bottom.

(6) transparent plastic parts set push rod considerations are as follows.

-Standards compliant

Manufacturing diameter from φ0.01mm-φ650mm, tolerance can be controlled to ± 0.001

The longest manufacturing length is 1500mm

Manufactured in Inch size also for specials and custom parts.

According to the part design, the maximum concentricity can reach 0.002.

Surface finish:Ra0.2-Ra0.8

Slow walking wire reaches tolerance ± 0.001

EDM tolerance can reach ± 0.002

-material(Choose according to customer requirements)

German Chinese British France Italy Swedish Spanish Japan American Austria 1.2379 CR12MOV BM2 Z85WDCV06-05-04-02 X165CRMOW12KU 2310 X160CRMOV12 SKD11 D2 YG-carbide 1.2601 CR12 BT4 Z80WKCV10-05-04-01 X82WMO0605KU 2722 HS6-5-2 SKH-9 D3/A2 WF-carbide 1.2713 W6MO5CR4V2 BM42

HS6-5-2-5 2723 HS6-5-2-5 SKH-51 M2 ceratizit 1.2833 W6MO5CR4V2CO5 BM2

ASPPM-23(ASP23) HS18-0-1 SKH-55 M3

1.3243 W18CR4VCO5 BT1

ASPPM-30(ASP30)

SKH-59 M42

1.3343 W18CR4VCO5

ASPPM-60(ASP60)

D-carbide CD-carbide

1.3348 W6MO5CR4V3

ASSB 88

1.3355 YT-carbide

H-carbide

S-carbide YG-carbide

Product Categories : Precision Grinding > Surface Grinding

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.