Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

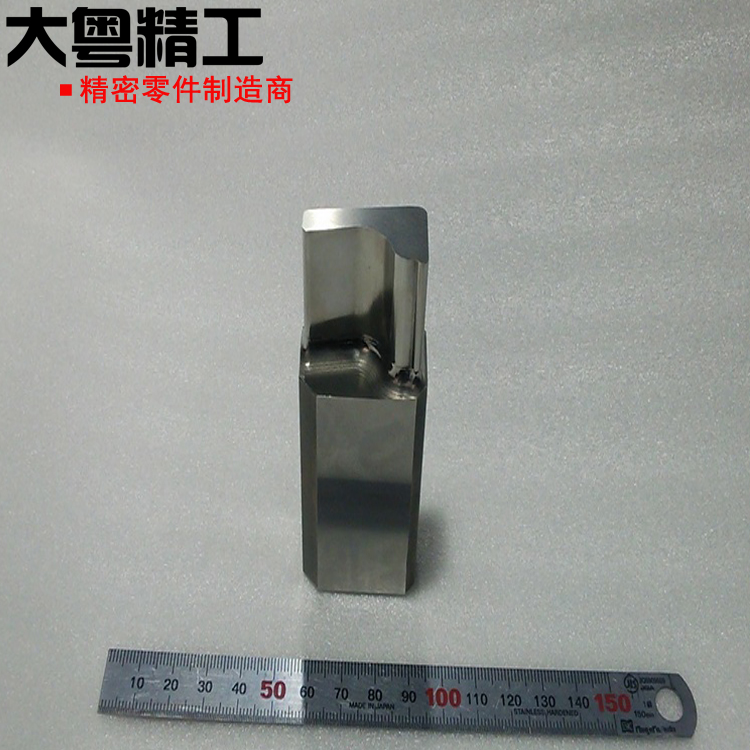

Model No.: DAYUE134

Brand: DAYUE

Application: Machinery Accessory

Standard: ASME

Surface Treatment: Polishing

Production Type: Batch Production

Machining Method: Other

Material: Other

Packaging: Vacuum Packing

Productivity: 100 pieces a day

Transportation: Ocean,Land,Air

Place of Origin: Dongguan

Certificate: ISO9001

Port: Yantian

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

DAYUE With 25 years of Mold Parts processing experience, we produce components in the entire mold industry and medical industries. DAYUE provides components of various practice areas, including orthopedics, minimally invasive surgery, interventional therapy, diabetes, ophthalmology, dentistry, drug delivery, bottle cap molds, blow molding molds, atomizing pump molds, pen making molds, daily packaging Product molds, medical molds, etc. Our additional services include CNC Machining, Hard Turning, internal and external grinding, honing, lapping, engraving, internal and external thread grinding, milling, nano-drilling, EDM, deep gun drilling and centerless and feed-through grinding.

We are used in three subsidiaries in China and have implemented high standards of quality control to ensure that our components are manufactured to the exact specifications of our customers. Whether it is manufacturing Core Pins, punch pins, Ejector Pins, medical pins, punch pins, drawing pins, suction cup pins, grommet pins, mold parts, mandrels, Ejector Sleeves or custom orders – our technology enables us Capable of manufacturing parts with dimensional tolerances of +-0.001. By implementing modern manufacturing technology, we can use ISO, DIN, JIS and other standards to create the required components and deliver them quickly so that you have what you need when you need it.

-Product information

OEM Mold Components & punch and dies machining

-Standards compliant

Manufacturing diameter from φ0.01mm-φ650mm, tolerance can be controlled to ± 0.001

The longest manufacturing length is 1500mm

Manufactured in Inch size also for specials and custom parts.

According to the part design, the maximum concentricity can reach 0.002.

Surface finish:Ra0.2-Ra0.8

Slow walking wire reaches tolerance ± 0.001

EDM tolerance can reach ± 0.002

-material(Choose according to customer requirements)

Iron,Cast iron.Copper,Stainless steel,Tungsten carbide, steel,Aluminum,WS,HSS,HWS Other non-ferrous metal (According to customer ne4-achsige Bearbeitung von Rotorwelleneds)

Product Categories : Press Die Components > Punches and Dies

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.