Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

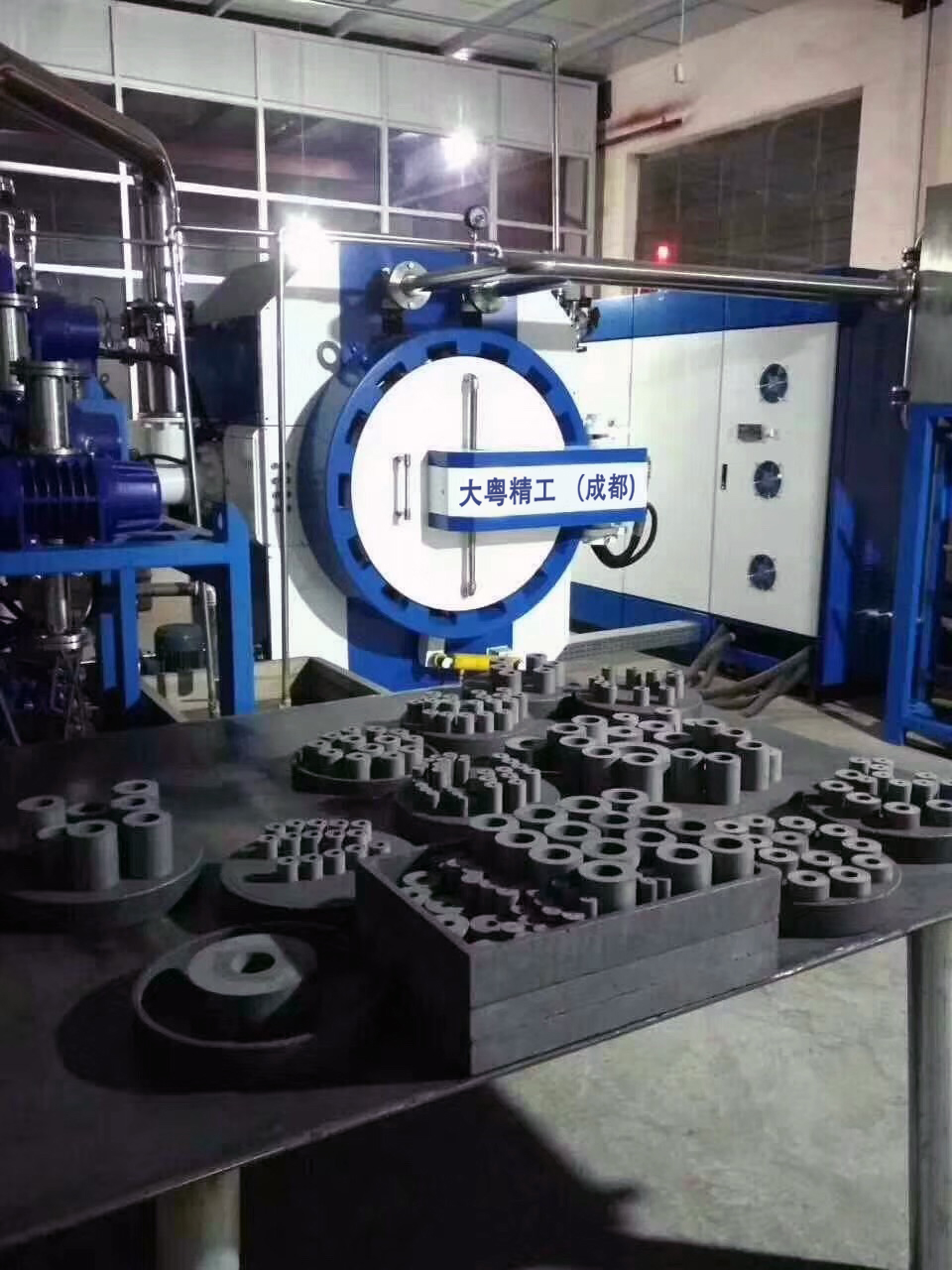

The manufacturing of DAYUE mold parts generally goes through several processes such as forging, cutting, and heat treatment. In order to ensure the manufacturing quality of mold parts and reduce production costs, the material should have good forgeability, cutting workability, hardenability, hardenability and grindability; it should also have small oxidation, decarburization Deformation cracking tendency during quenching.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.