Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DAYUE134

Brand: DAYUE

Application: Machinery Accessory

Standard: ASME

Surface Treatment: Polishing

Production Type: Batch Production

Machining Method: Other

Material: Other

Packaging: Vacuum Packing

Productivity: 100 pieces a day

Transportation: Ocean,Land,Air

Place of Origin: Dongguan

Certificate: ISO9001

Port: Yantian

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

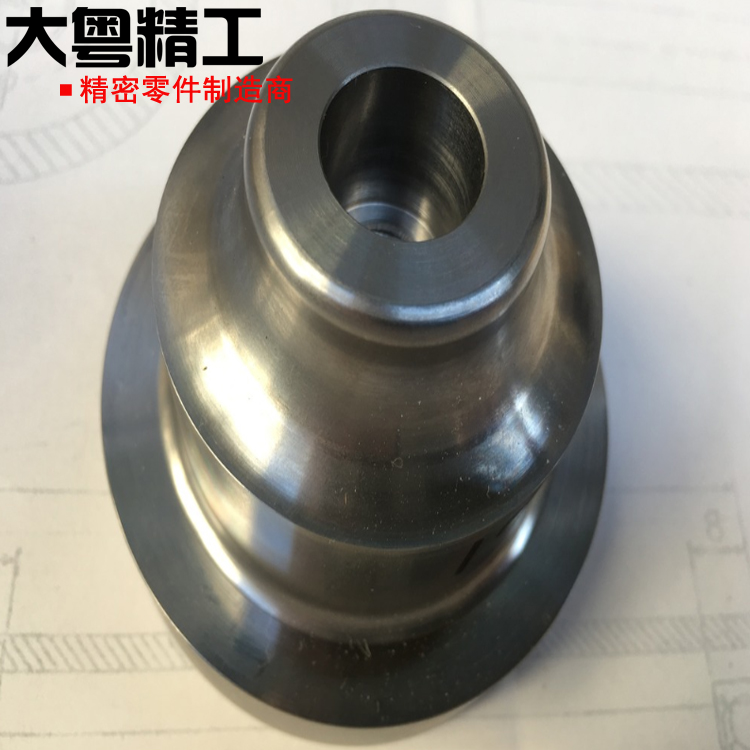

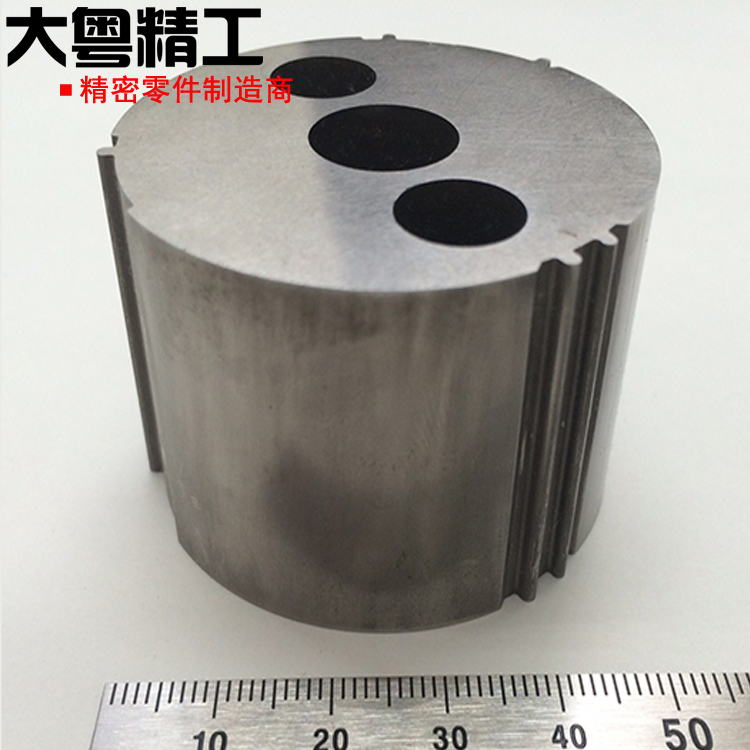

OEM precision Mold Components die punch, customized components according to customer drawings, providing CNC precision machining,grinding,WEDM,EDM services.

DAYUE Precision Technology Co., Ltd. is one of China's most outstanding mechanical processing manufacturers and suppliers. "Solving all precision parts manufacturing problems" is the value of every employee of DAYUE. After 26 years of development, we have three subsidiaries in China to better provide mechanical machining services worldwide.

Provide high-quality CNC Turning , CNC Milling, 4-axis and 5-axis CNC Machining, Hard Turning, external grinding, Internal Grinding, Centerless Grinding, honing, contour grinding, fixture grinding, deep hole drilling and gun drilling , Micro Manufacturing, EDM, WEDM, boring, gear hobbing, Custom Metal Stamping,Aluminum Extrusion,Die Casting and Forging,Sheet Metal Fabrication,Gear Grinding and other services

-Product information

Components for molds material 1.3343,

According to the customer's drawings or samples (non-standard parts) or series number (standard parts), we will quote you on the same day.

If the document belongs to intellectual property and confidential information, we can sign the NDA.

-Certified

ISO 9001/IATF 16949

-Standards compliant

Manufacturing diameter from φ0.01mm-φ650mm, tolerance can be controlled to ± 0.001

The longest manufacturing length is 1500mm

Manufactured in Inch size also for specials and custom parts.

According to the part design, the maximum concentricity can reach 0.002.

Surface finish:Ra0.2-Ra0.8

WEDM tolerance ± 0.001

EDM tolerance can reach ± 0.002

-material(Choose according to customer requirements)

Woods: cherry, pine, ash, oak, and more

Plastics: polyvinyl chloride (PVC), acrylic sheets, nylon, polycarbonate, polypropylene, PTFE, and more

Metals and allows: steel, stainless steel, copper, titanium alloy,aluminum, brass, ,tungsten carbide,cemented carbide,and more

Product Categories : Press Die Components > Die Guide Components

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.